Factory price ramming mass silica for induction furnace blast runner

Refractory ramming mass is made up of refractory aggregate and powder,binder and additive proportionally,using ramming method during construction.

1.Refractory aggregate:fire clay based,high alumina based,mullite-corundum based,silica based,magnesia based,carborundum based etc

2.Binder:phosphoric acid and phosphates, sodium silicate, aluminum sulfate,binding clay and organic binder etc.

Feature of Our ramming mass:

1. High refractoriness and excellent mechanical strength.

2.High density,not easy leakage,

3.Excellent thermal shock resistance stability,

4.Good volume stability at high temperature,

5.Excellent erosion resistance,

6.Good slag resistance,

7.Longer and stable service life cycle to reach high efficiency.

Product Applications:

Magnesite ramming mix is used for the lining of smelting furnace etc thermal equipment such as ,Blast furnace iron runner and slag runner,Hot-blast cupola furnace,Lining of blast furnace,Molten steel ladle,Electric arc furnace(EAF),Matte smelting everberatory furnaces, Lining of inductionfurnace,Converter,Steel refining furnace,Rotary kiln etc.

This is only part of the parameter, and there are detailed requirements to inform me so that you can provide detailed parameters for you.

| Ramming material | High alumina | Magnesium | Magnesia- chrome | Magnesia-alumina-chrome | Corundum Chromium zircon | Alumina- zirconia | |

| Chemical Composition % | Al2O3 | 83 | 2.3 | 6 | ≤15 | 74 | 68 |

| ZrO2 | 1.1 | 93(MgO) | 59(MgO) | 55-60(MgO) | 6.6 | 11 | |

| Cr2O3 | - | - | 16 | 15-20 | 15 | - | |

| Compressive strength MPa | 110°C | 38.5 | 62 | 43.5 | 74.1(150°C) | 5.0 | 26.5 |

| 1000°C | 47.6 | 54 | 25.8 | 32 | 62.2 | 42.6 | |

| 1600°C | 67.2 | - | 38.5 | 53 | 123.2 (1500°C) | 38.4 (1400°C) | |

| Refractoriness under load °C | - | - | 1500 | - | 1700 | 1340 | |

| Reheating linear change % | +0.60 | -0.15 (1600°C) | -0.60 | -0.14 | - | +0.93 (1400°C) | |

| Apparent porosity % | - | 14 | 13 | - | 15 | 23 | |

| Bulk density g/cm3 | 2.70 | 2.95 | 2.70 | 3.05 | 3.33 | 2.70 | |

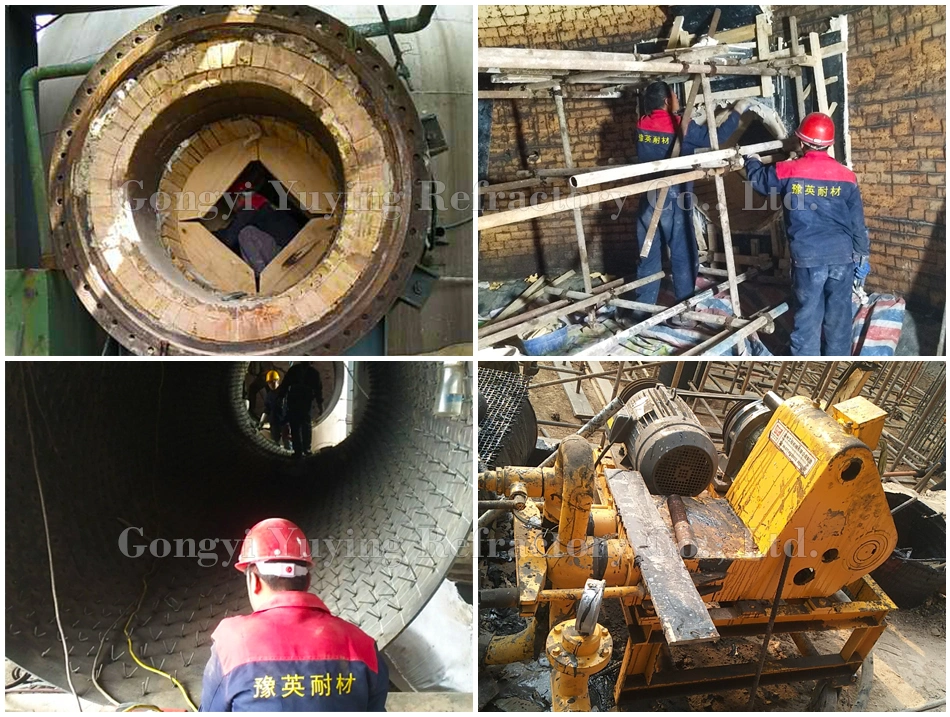

Our Factory:

Product Packing and Delivery:

- Big bag :500kg/1000kg jumbo bag

- Small bag:25kg/20kg PP bag

- 25kg Kraft paper bag

- According to your requirements

1.20GP FCL :25TONS

2.40GP FCL: 25-26TONS

3.40HQ FCL:25 TONS or 26 TONS

The above quantity without pallet ,the goods will be sent within 7-15days after receiving your order.

Our certificate: