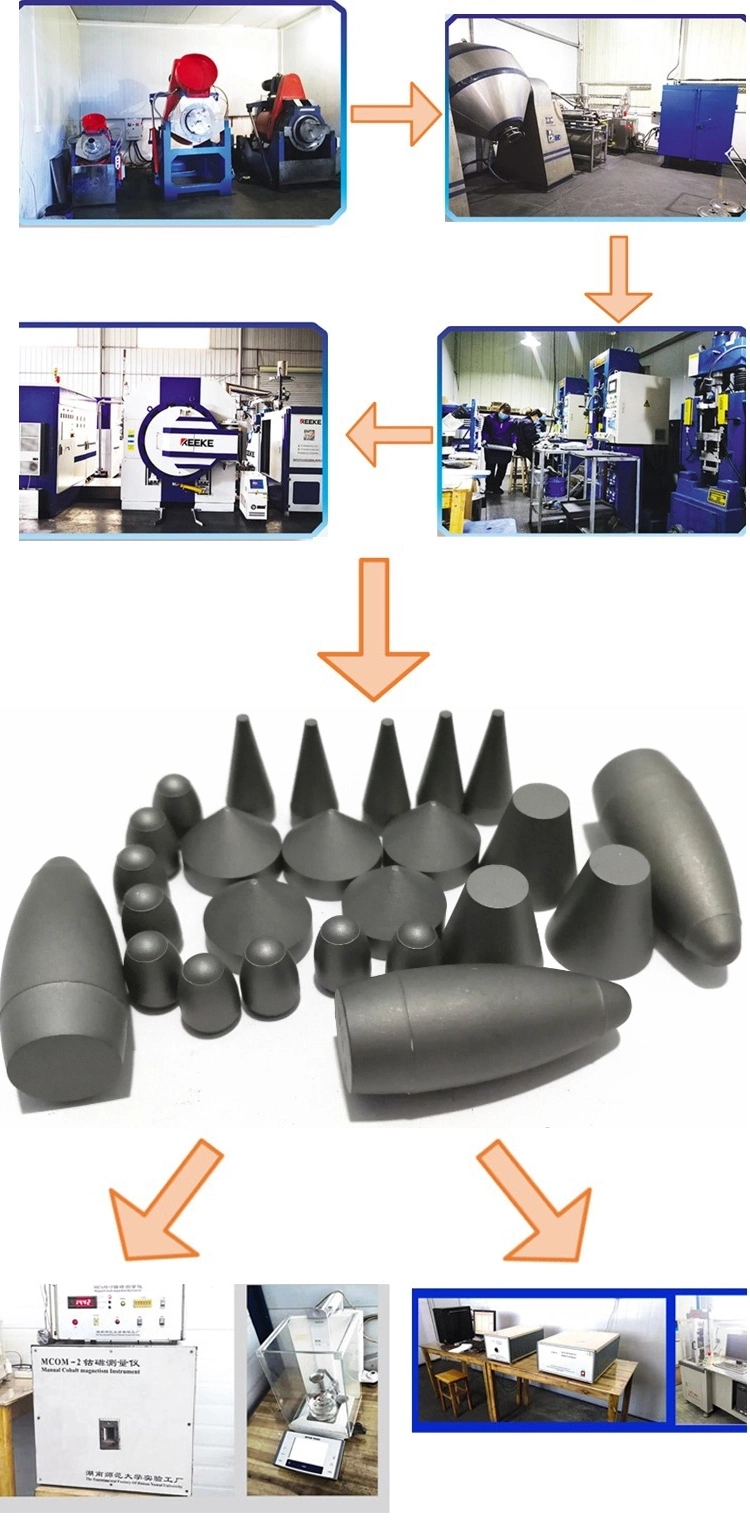

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

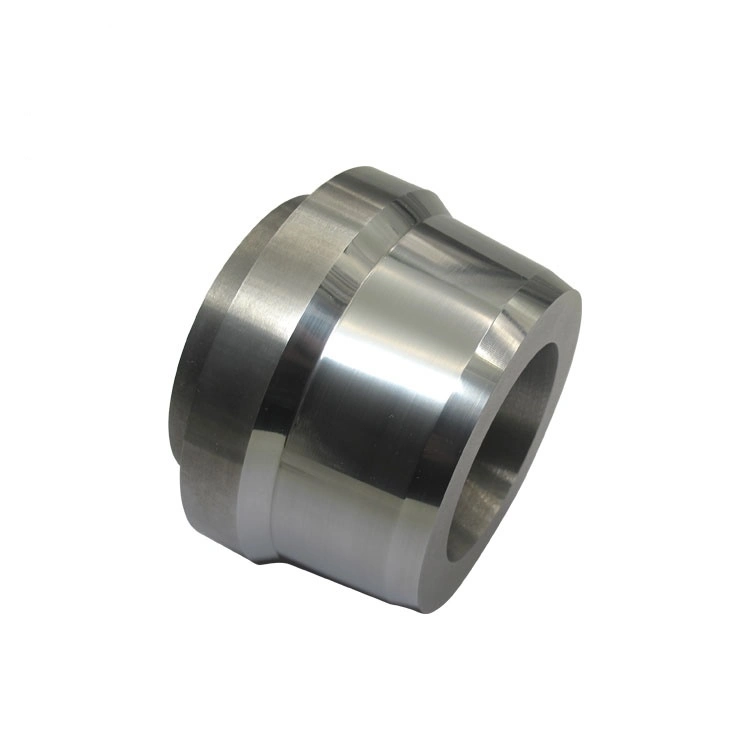

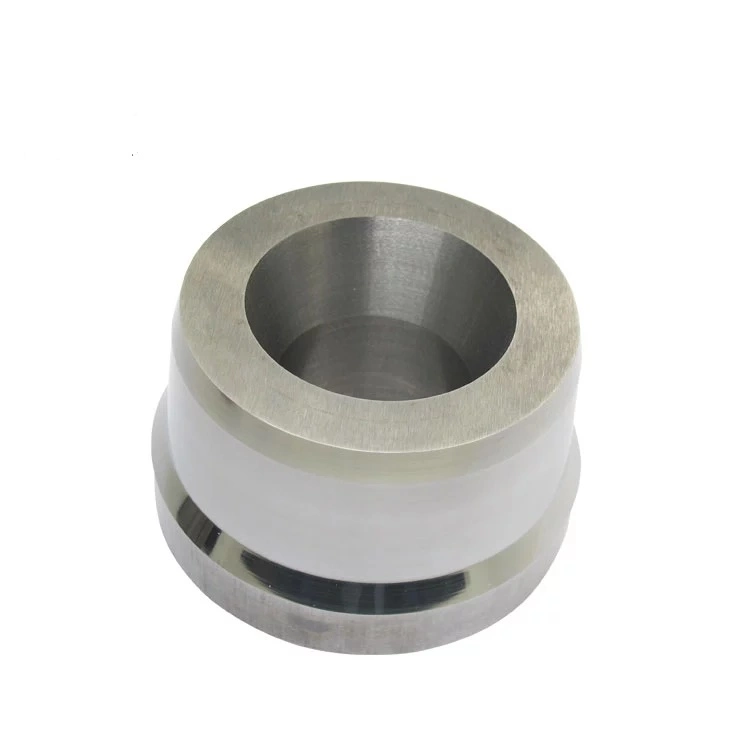

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Material Grade List

Grade | Co% | Density (g/cm²) | Hardness (HRA) | TRS (N/mm²) | Application |

XD20A | 9.0 | 14.53-14.73 | 89.0-90.0 | ≥2400 | For making buttons for tri-cone drill bits with both high wear resistance and toughness. |

XKH20 | 10.0 | 14.45-14.60 | 87.5-89.5 | ≥2600 | For making gauge row buttons of various tri-cone drill bits. |

XD20B | 10.0 | 14.43-14.63 | 88.8-89.5 | ≥2300 | For making buttons for tri-cone drill bits with both high wear resistance and toughness. |

XD30 | 10.0 | 14.43-14.63 | 88.1-89.1 | ≥2000 | For making buttons for tri-cone drill bits with both high wear resistance and toughness. |

XD40 | 10.0 | 14.10-14.60 | 87.2-88.2 | ≥2900 | Used in buttons for bits drilling in medium hard to soft rock formations. |

YG11C | 11.5 | 14.25-14.45 | 86.5-88.0 | ≥2400 | Coarse grade, used for inserts for bits drilling in medium hard to hard rock formations. |

XD45 | 12.0 | 14.23-14.43 | 86.8-87.7 | ≥2500 | Medium coarse grade, used for inserts for bits drilling in hard rock formations. |

YG13C | 13.0 | 14.15-14.35 | 85.5-87.0 | ≥2450 | Mainly used for making cemented carbide buttons for drilling medium hard and hard rock formations. |

XKH60 | 16.0 | 13.85-14.00 | 85.0-87.0 | ≥2700 | Used for buttons for inner rows in bits drilling in medium hard to soft rock formations. |

XD60 | 16.0 | 13.85-14.00 | 85.0-86.5 | ≥2500 | Used for buttons for inner rows in bits drilling in medium hard to soft rock formation |